Leakage protection for many flange sealing surfaces, flanges with standard roughness as well as painted and enameled flange surfaces, simple and economical use

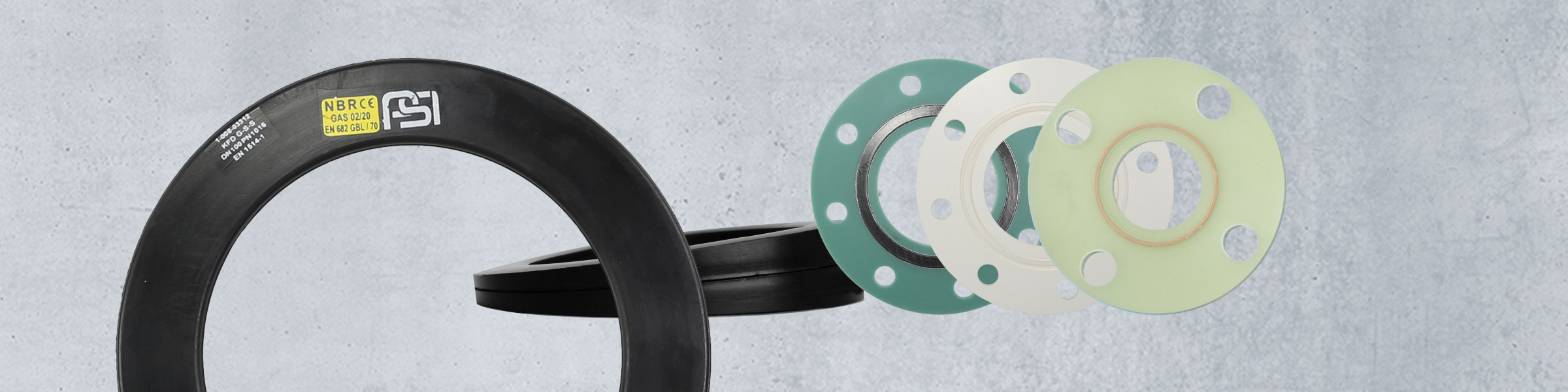

GaskiT

Flange gasket/isolation

Type selection

GaskiT KFD - Rubber Steel Gasket (G-S-S)

Fields of application

Sealing of flange connections for gas supply systems, drinking water systems, hydrogen pipes, service water, wastewater and pumping station systems

Material

Elastomer materials made of EPDM: hardness Shore A: 70° ±5,

operating temperature from -25 °C up to +120 °C;

elastomer materials made of NBR: hardness Shore A: 70° ±5,

operating temperature from -25 °C up to +90 °C

Properties

Gaskets for more dimensional stability due to vulcanized steel ring;

gasket dimensions according to DIN 1514-1 / DIN 2690; for safe centering within the bolt ring; fast sealing effect at low bolt tightening torque due to bead on the medium side; compensation of pressure changes and variations in temperature due to high resilience

Sizes

ND 15 - ND 1200 (up to ND 2000 on request);

pressure ratings PN 6 - PN 40

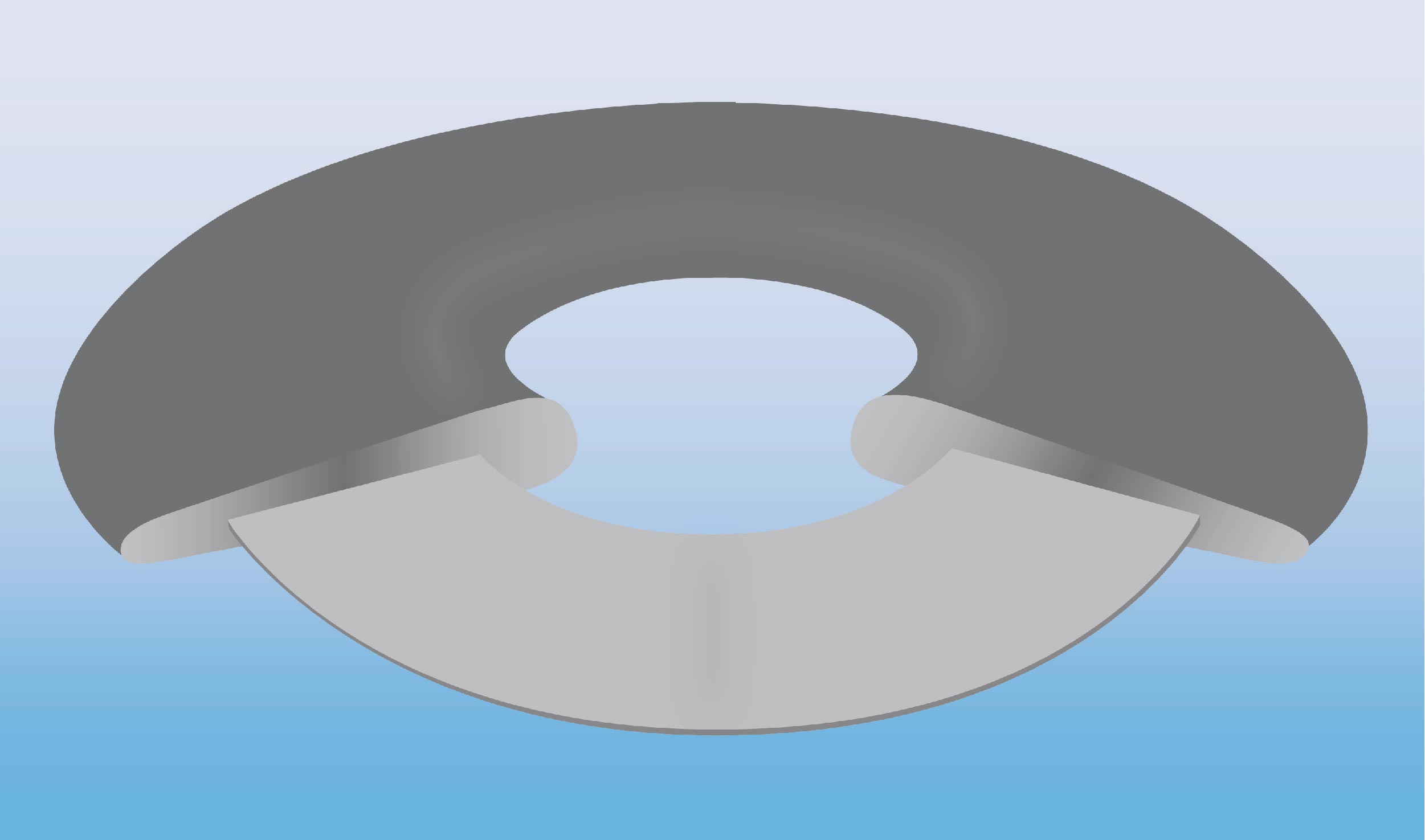

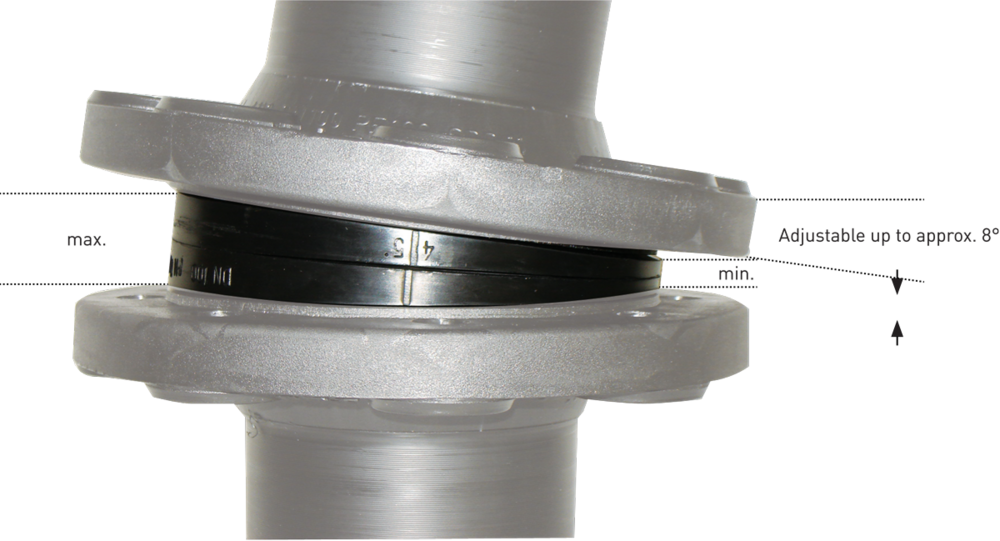

GaskiT WD - Adjustable Rubber Steel Gasket

Fields of application

Sealing of flange connections for water, wastewater and pumping station installations

Material

Elastomer materials made of EPDM; operating temperature from -25 °C up to +120 °C

other elastomer materials e.g. FKM (Viton) on request

Properties

Easy to use for flange misalignment; each gasket consists of two segments connected by a tongue-and-groove connection; adjustment range by rotating the two parts in opposite directions up to 8 degrees;

replaces the wedge disks commonly used in such cases, and the additional gasket in a simple and economical way; gasket dimensions according to DIN 1514-1; for safe centering within the bolt ring.

Sizes

ND 32 - ND 500, Pressure ratings PN 10 - PN 40 (large nominal Sizes PN 10)

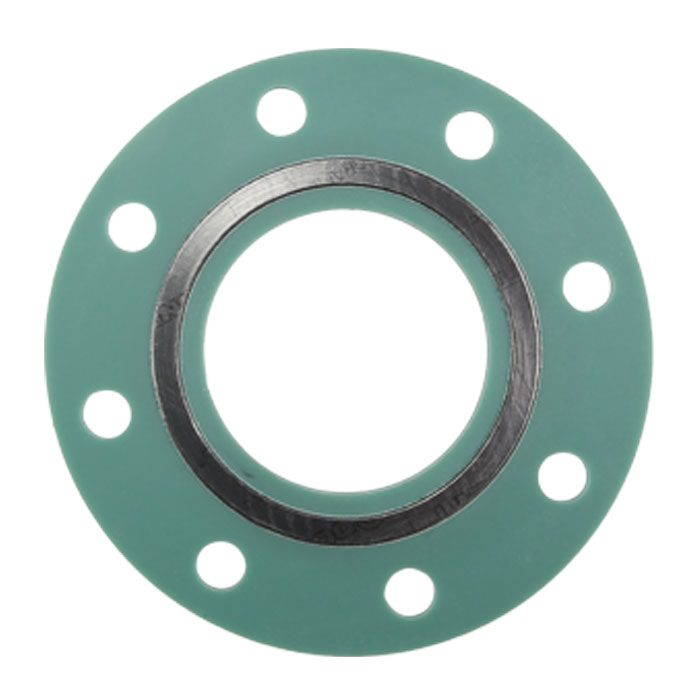

GLV UniSeal GGR® - Flange Isolation

Fields of application

Sealing of flange connections in the field of gas supply; tank installation; oil supply; and electrical separation.

Material

Retainer made of epoxy resin-bonded glass filament laminate; sealing-material made of expanded graphite

Properties

Indirect bolt force load flange insulating gasket; fulfills the requirements of the technical rules for flammable gases and liquids; functionally safe due to minimum water absorption; blow-out safe due to chambered sealing rings inside grooves; gasket type E with bolt holes according to the flange standards; gasket in design type F without bolt holes according to the flange standard (IBC Inner Bolt Circle); compressive strength up to 500 MPa (at +20°C); thickness 4 mm (8, 16 and 20 mm on request); operating temperature from -60 °C up to +150 °C

Sizes

ND 25 - ND 900; PN 10 - PN 63 (EN 1092-1) / ½" - 40";

CLASS 150 - 400 (ANSI B16.5 + B16.47);

Other nominal and special sizes on request

GLV UniSeal GGR® - Flange Isolation

Fields of application

Oil & Gas industry, tank installation, applicable in the field of electrical isolation and/or sealing of flange connections

Material

Retainer made of epoxy resin-bonded glass filament laminate with a thickness of 4 mm; sealing material made of high-temperature resistant.

Properties

Flange isolation gasket; indirect bolt force load; functionally safe due to minimal water absorption; blow-out safety due to chambered sealing rings inside grooves; gasket type F for inner bolt circle installation; compressive strength up to 500 MPa (at +23 °C); operating temperature from -60 °C up to +150 °C (depending on operating medium); gasket can be used with flanges according to Standard EN 1092-1

Sizes

ND 25 - ND 300 Up to ND 80: PN 10 - PN 40, ND 100 - ND 300: PN 10 - PN 16

Other nominal and special sizes on request

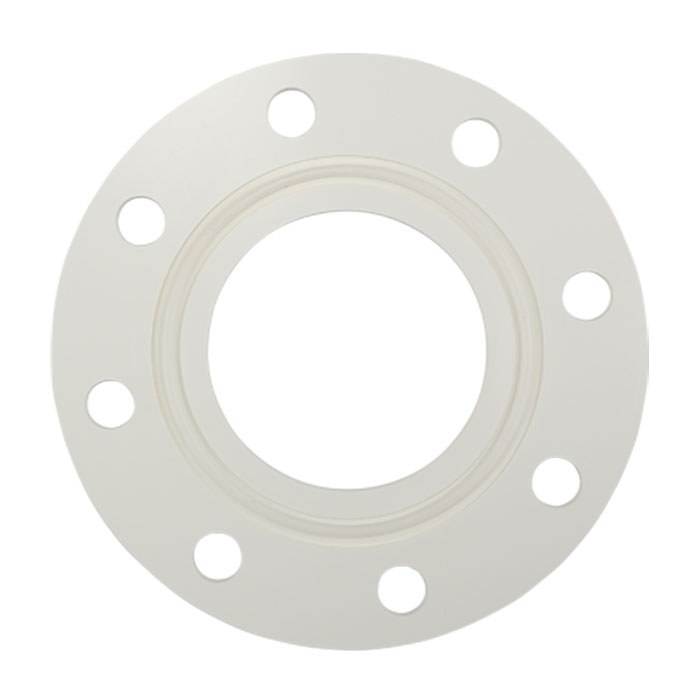

GLV UniSeal T® - Flange Isolation

Fields of application

Water supply, drinking water, wastewater, in the area of electrical separation and/or sealing of flanged connections.

Material

Retainer made of PVC; sealing material made of silicone RTV1-02; permanently elastic

Properties

Flange Isolation gasket; indirect bolt force load; functionally safe due to minimal water absorption; pressure resistance up to 130 MPa (at +20 °C); thickness 4-6 mm (4 mm up to ND 250 / 6 mm from ND 300); operating temperature up to +60 °C

Sizes

ND 25 - ND 1200; PN 10 - PN 40 (EN 1092-1) / ½" - 42";

CLASS 150-300 (ANSI B16.5 + B16.47);

Other nominal and special sizes on request

GaskiT Isolation KIT

Fields of application

Isolation/electrical separation of flange connection bolts

Material

Isolation KIT consist of one isolation sleeve;

2 isolation washers and 2 steel washers for each bolt hole.

Properties

Easy installation on site; optimal electrical separation;

extreme strength; no increase of bolt diameter;

operating temperature up to 130 °C (higher temperatures on request).

Sizes

ND 20 - ND 600, PN 10 - PN 63;

Composition of isolation washers; steel washers and isolation sleeves

according to DIN/ANSI flange requirements.

Download

Product Information

Properties

- High operational safety

- Low tightening torques

- Dimensional stability

- Large operating temperature range

Fields of application

Sealing and isolation of flange connections in corrosion protection plants, for electrical separation. Flange Isolation for cathodic corrosion protection of flange sealing surfaces in combination with isolation sleeves and isolation washers. Flange Isolation to meet the requirements of technical regulations for flammable gases and liquids. The flange gaskets GLV-UniSeal® T and GGr can, of course, also be used as gaskets without Isolation.

Description

Easy and quick installation. Can be mounted with "standard tools" and torque wrench.

Technical Information

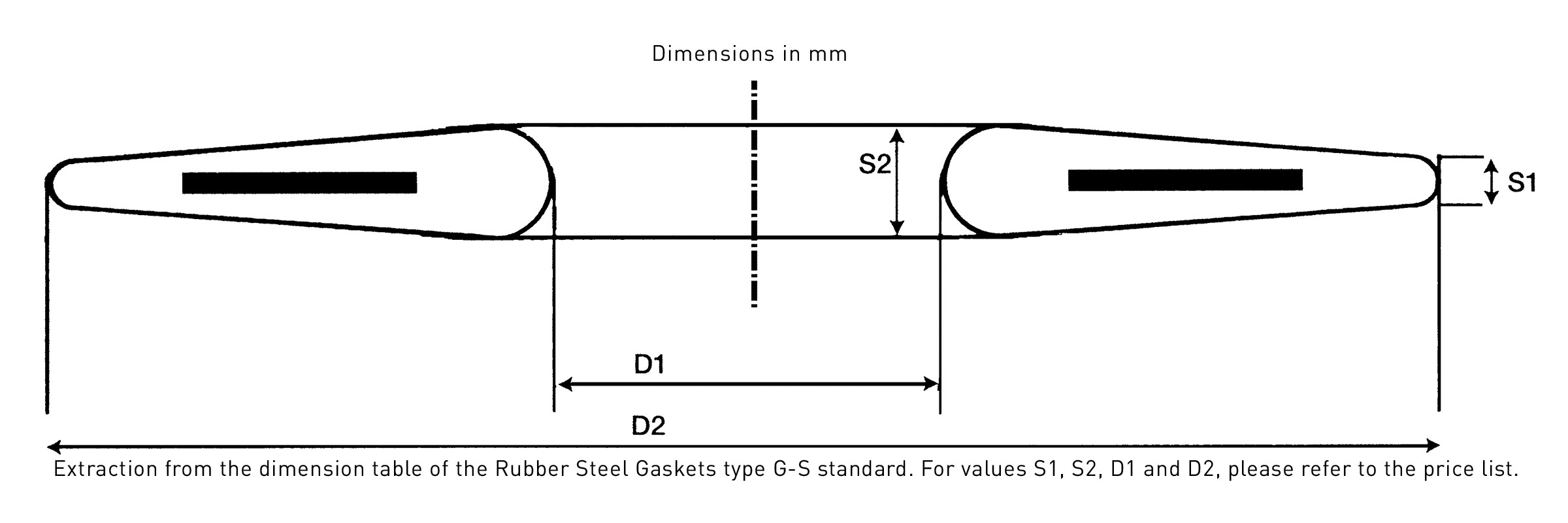

GaskiT KFD - Rubber Steel Gasket

Rubber Steel Gasket G-S-S with vulcanised steel ring for more dimensional stability, safe centering and perfect sealing according to DIN EN 1514-1 (PN 6-40).

Gaskets according to DIN 1514-1 / 2690. For dimensions from ND 15 to ND 1200 (up to ND 2000 on request). For pressure ratings from PN 6 to PN 40.

Rubber Steel Gasket Typ G-S-S

With vulcanized steel ring according to DIN EN 1514-1: Form IBC for pressure ratings from PN 6 to PN 40.

Two in one

Due to its wedge shape, the PSI rubber-steel gaket GASKIT KFD can be used as an alternative to the so-called

O-ring seal, and as a standard rubber-steel gasket.

GaskiT WD

Certificates

To offer our customers the best possible quality and service, we are organized according to DIN EN ISO 9001:2015 and have this continuously checked and certified.

CERTIFICATE ISO 9001:2015

This certification documents our conformity of the quality management system.

AEO-CERTIFICATE

Authorized Economic Operator "AEOC (customs simplification)"

DECLARATION OF PERFORMANCE

KFD EPDM

KFD NBR

Flange gaskets

- KFD NBR; EN 682-1, DVGW VP406 A7; DIN-DVGW type examination certificate

- KFD EPDM; DVGW W270; Test report TZW

- KFD EPDM: Material according to Standard EN 681-1; Hot-Water Resistant

- WRAS: Material Approval

- ACS: Certificate of sanitary conformity

Flange Isolations

- GLV UniSeal GGr: DIN DVGW Cert; TA-Air-Compliant

- GLV UniSeal T: DVGW W270 and UBA silicone transition recommendation for preliminary drinking water hygiene assessment

- LineBaker: Leakage Test Report according to EN 13555

- Pikotek® VCFTM: TA-Luft according to VDI 2200 (2007-06)

- Pikotek® VCFSTM : TA-Luft according to VDI 2200 (2007-06)

- Fire Test Report according to API 6FB

- HTB confirmation according to DVGW VP401, chapter 4.6.3